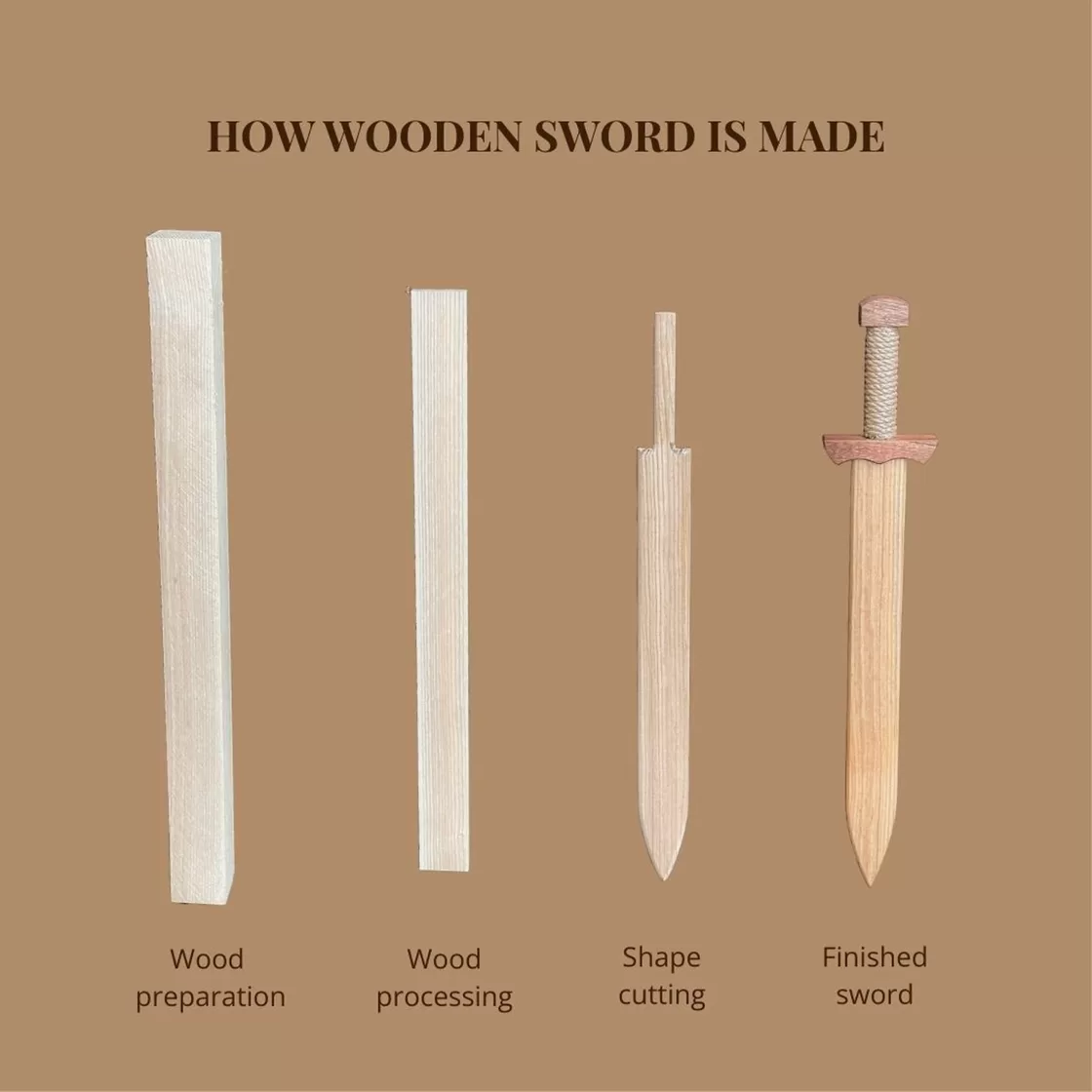

How a wooden sword is made

In this article, we show how EO Wood wooden swords are made — from an unprocessed piece of wood to a finished product.

We highlight the main steps the wood goes through in the making process and explain what materials we use and what we pay attention to, so that the sword is safe and pleasant to use.

The entire process from A to Z is handmade, and each sword is individually crafted!

1. Sourcing and preparing the timber

For making wooden swords, we use high-quality wood purchased in Latvia, such as ash, oak, American white oak and sapele. These woods are very durable, making them ideal for crafting toys.

2. Cutting the sword shape

Each sword shape is cut manually on a band saw.

This is when a simple wooden board begins to take the silhouette of a sword.

3. Rounding the edges

So that the sword is safe for children, all edges are carefully rounded.

At this stage, we use a router to create even curves without sharp corners.

4. Sanding

After shaping, the entire surface of the sword is sanded with a sander.

This step ensures the wood is completely smooth and pleasant to the touch, with no splinters or roughness.

5. Finishing the handle

Jute thread is wrapped around the sword’s handle.

This improves grip, gives character to the sword and keeps the aesthetic natural and simple.

6.

Applying linseed oil finish

In the final stage of production, the sword is coated with linseed oil.This highlights the wood’s natural texture and adds protection to the surface.

You can view the finished EO Wood wooden swords in our shop.